With the rapid development of vacuum technology, vacuum pumps have entered factories in many industries for transportation, production, experiments, etc. During the operation of the vacuum pump, if foreign matter is sucked in, it is easy to "strike". Therefore, we need to install filters for vacuum pumps. It should be noted that there are many types of vacuum pump filters. Before purchasing filters, first clarify what the impurities are.

There are various types of vacuum pump filters, among which the inlet filter includes a powder filter and a gas-liquid separator. If water vapor is sucked into the pump, it will mix with the pump oil; and then the purity of the pump oil will decrease, resulting in the loss of lubrication or sealing function. Powder not only pollutes pump oil, but may also wear down blades. If it is a sticky gel, the filter material and even the design may be different. If you want to filter oil mist and prevent it from polluting the environment by being released into the atmosphere, then most likely you need an exhaust filter.

So before choosing a filter, be clear about what you want to filter. In addition, it is important to know the pumping speed (flow rate), vacuum degree, inlet temperature, etc. of your pump, as this will help suppliers select suitable products for you.

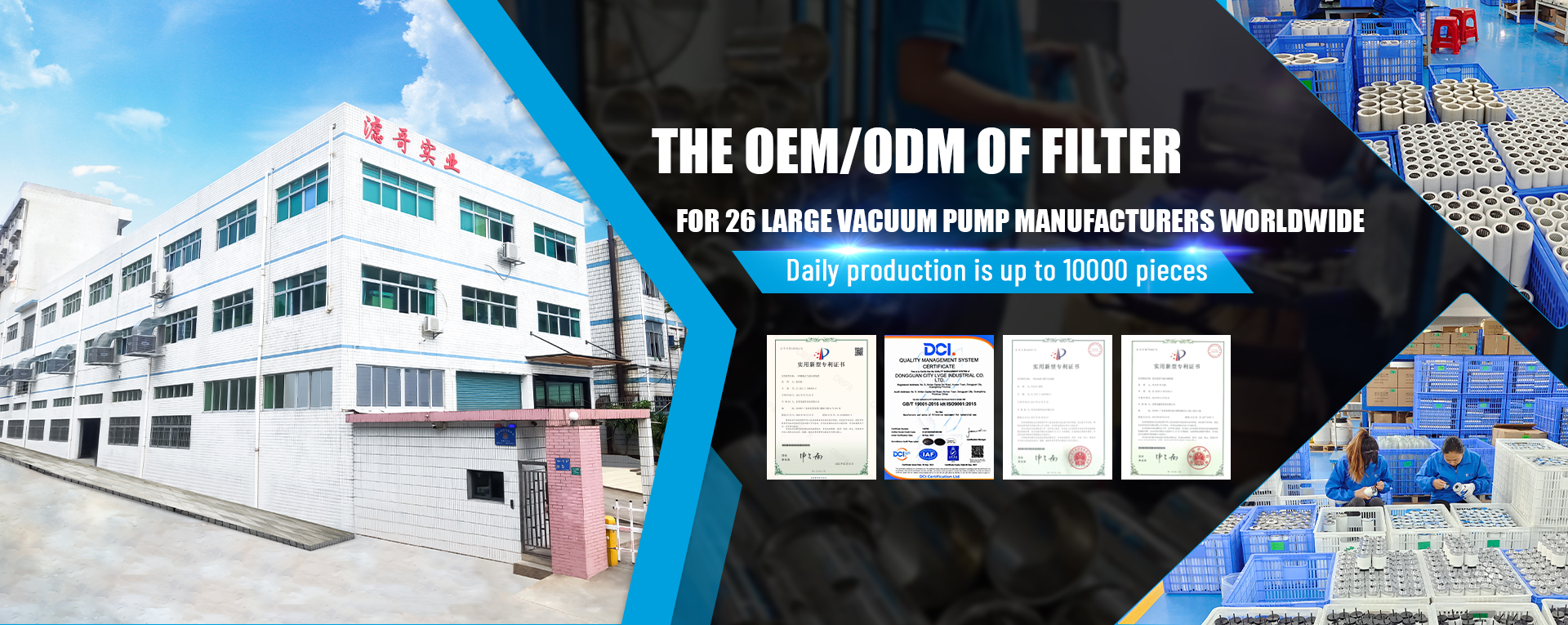

Choosing a reliable vacuum pump filter supplier is also important. LVGE, it have been established for 13 years and our technical team has over 20 years of experience. We specialize in designing various vacuum pump filters and are committed to providing you with suitable filtration solutions. Some manufacturers recommend inferior or unsuitable products due to low customer budgets. For us, if we are not competent, we will truthfully tell our clients that we are not able to solve it. If your filter cannot solve your problem well, just consult us.

Post time: Jan-20-2025