Vacuum coating technology is an important branch of vacuum technology, commonly used in industries such as construction, automotive, and solar chips. The purpose of vacuum coating is to change the physical and chemical properties of the material surface through different films. The film produced requires year-round operation, so there are high requirements for the service life. To produce such a film, the coating system must have strong stability and reliability.

What are the applications of coating in real life? Taking glass as an example, it can radiate the energy of most natural light sources, which is beneficial for light collection and energy absorption. For space infrared radiation, although ordinary glass can prevent indoor heat from directly losing to the outside, after the heat is absorbed by the glass, a lot of heat will also be lost during the secondary heat dissipation process. Sunlight control film and low emissivity film can compensate for the shortcomings of ordinary glass in these aspects.

If there is dust on the surface of the workpiece, it will affect the overall effect of vacuum coating. So how can we reduce this dust?

1. Use raw materials that meet the purity requirements.

2. Control dust within the upper limit of the maximum technically permissible particle size and the amount of particulate matter per unit area.

3. Clean the substrate material.

4. Clean the vacuum chamber after coating for a period of time.

5. Keep low indoor air mobility and floor clean. If it is exposed cement ground, it needs to be covered and treated. Walls and roofs cannot be painted with ordinary gray paint.

6. Increase properly the humidity of the environment, which is beneficial for reducing the suspended solid particles in the surrounding environment.

7. Wear specialized work clothes, gloves and foot covers.

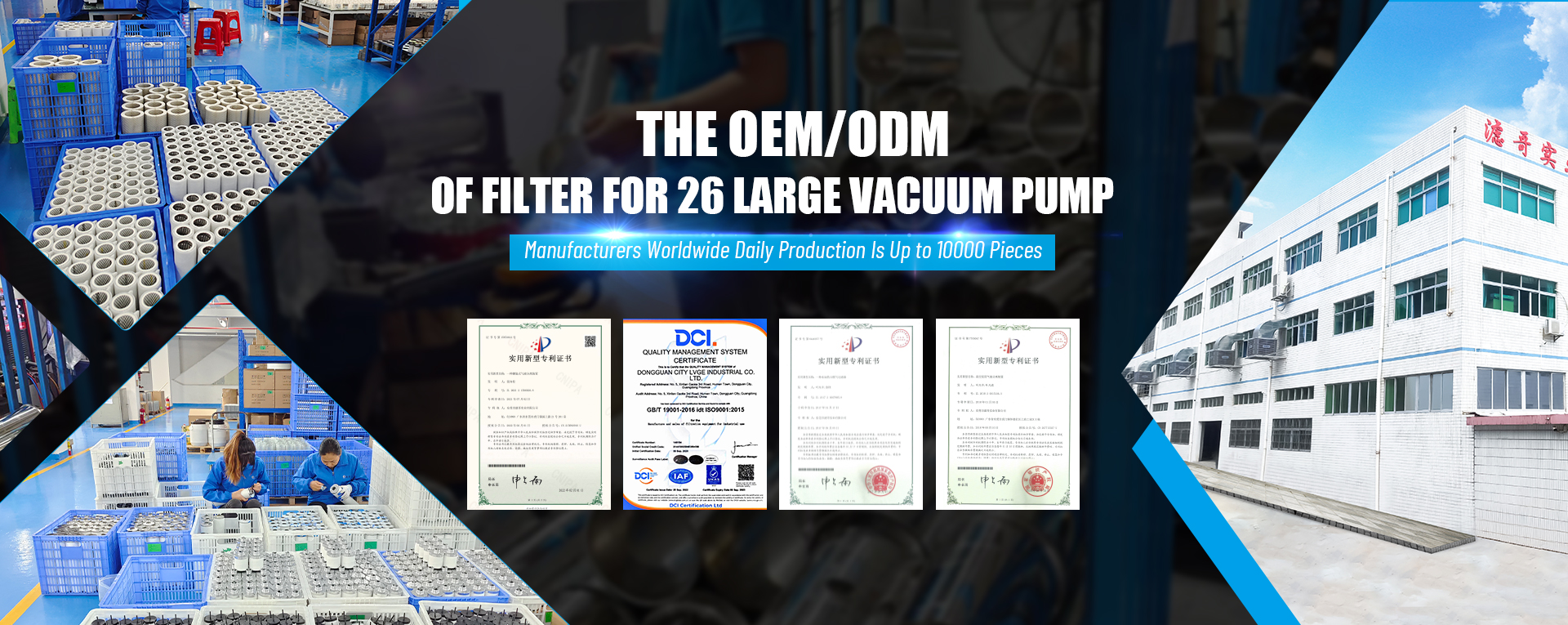

8. Configure high-quality dust filters for vacuum pumps.

China holds a 40% share in the global vacuum coating industry. LVGE has cooperation with many vacuum coating companies in China, like HCVAC, Foxin Vacuum, and Zhen Hua. Nowadays, we are also gradually moving towards the world, learning and seeking advice from foreign clients.

Post time: Jun-17-2024