Vacuum quenching is a treatment method in which raw materials are heated and cooled according to the process specifications in vacuum to achieve the expected performance. The quenching and cooling of parts are generally carried out in a vacuum furnace, and the quenching media mainly include gas (some inert gas), water, and vacuum quenching oil. During the quenching and cooling process, the vacuum pump inlet filter plays a crucial protective role.

The process of heating and cooling generates a large amount of steam and gas, which can affect the quality of vacuum quenching. If these gases are sucked in during vacuum pumping, the vacuum pump oil will be contaminated, the interior of the vacuum pump may be corroded, and the seals may also be damaged. Therefore, it is necessary to install a vacuum pump filter to filter out these water vapors and gases.

When choosing a vacuum pump filter for vacuum quenching process, it is necessary to choose a filter that is resistant to high temperature and corrosion. This is because the environment for vacuum quenching is usually high temperature. If the filter does not have the characteristics of high temperature resistance and corrosion resistance, the service life of the filter will be greatly shortened, and even cannot be used at all.

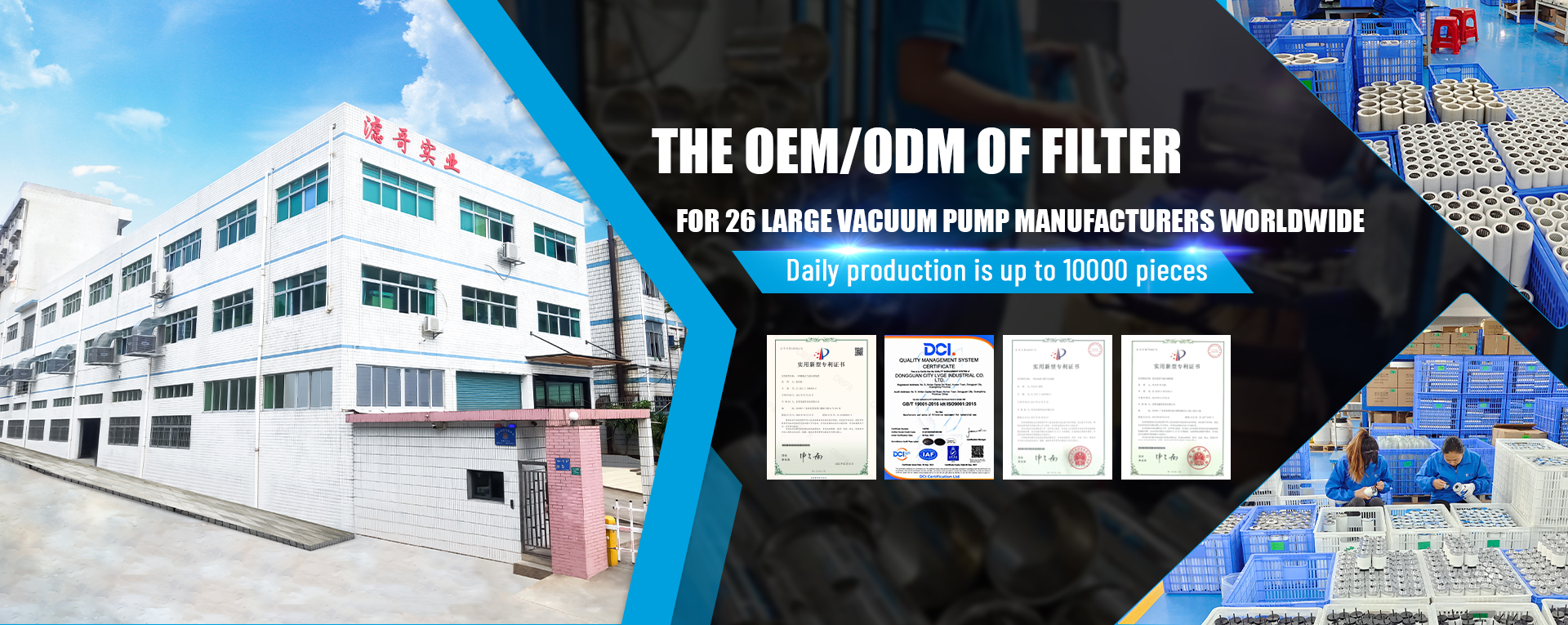

LVGE, a vacuum pump filter manufacturer with over 10 years of industry experience, specializes in designing and manufacturing various types of vacuum pump filters. We provide you with suitable vacuum pump filtration solutions for different working conditions.

Post time: Jul-13-2024