With the vacuum technology come out and be applied in industry widely, the development of our modern industry have be promoted. Many vacuum processes emerge as the times require, such as vacuum quenching, vacuum deaeration, vacuum coating, etc. The application of vacuum pumps and vacuum pump filters in industry is becoming increasingly widespread. Here, LVGE would like to share the knowledge of vacuum coating with you.

Vacuum coating refers to a method of heating materials under vacuum conditions, so that the materials evaporate and condense on the surface of the plating to form a film.

It has a wide range of applications. For example, some decorations in our daily life like phone cases, glasses frames and watchbands. They all have the shadow of vacuum coating. And in industrial production, some metal cutting of tools and molds also apply the vacuum coating technology - drill bits and milling cutters with different colors are formed by vacuum coating. In terms of building, the glass also apply the technology. The glass can achieve different effects by plating different films - plating sunlight control film can reduce the indoor temperature; plating low radiation film can prevent the indoor heat outflow.

In addition to these, vacuum coating technology has made achievements in the field of electronic products, optical applications and anti-counterfeiting, etc. It’s obvious that the technology is a very important presence in the vacuum process. If you want to apply these vacuum processes well, don't forget to equip the vacuum pump with a good filter. The intake filter can protect your vacuum pump and workpiece, while the exhaust filter can protect the environment and your health.

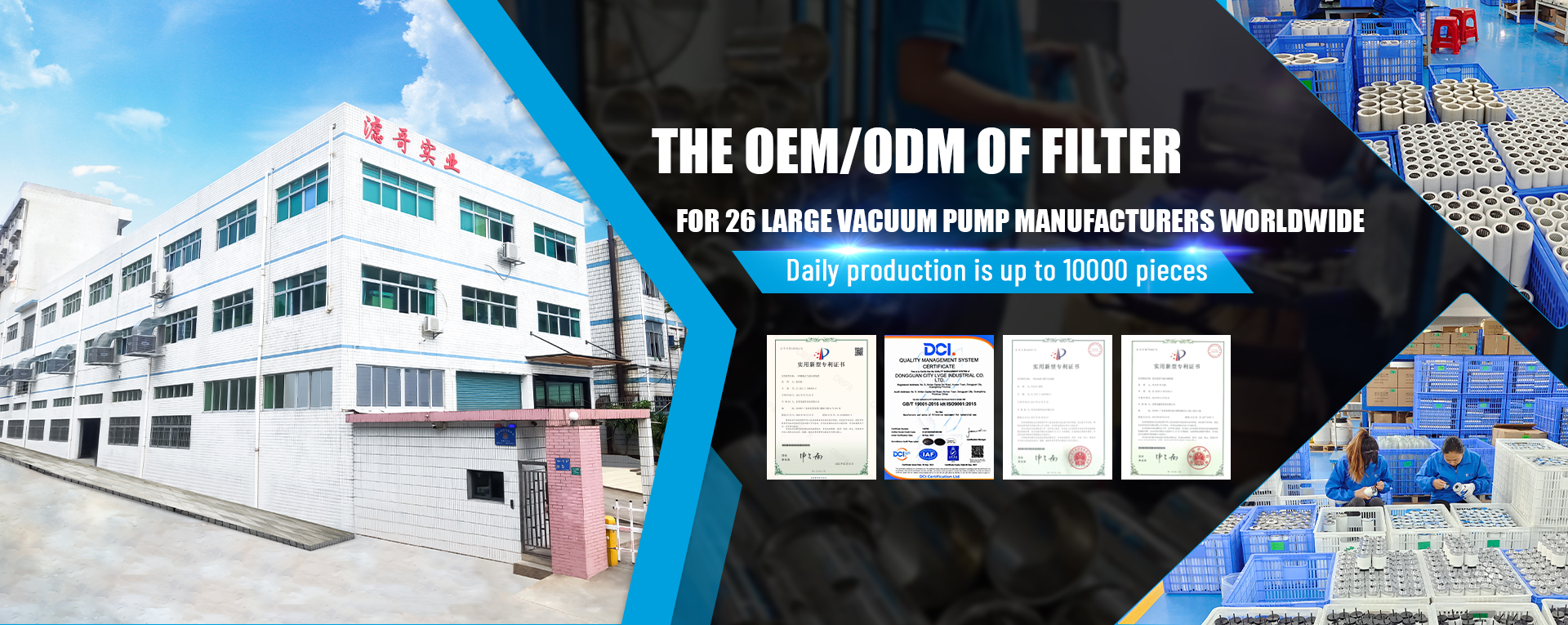

If you want to learn more, please follow LVGE. LVGE has over 10 years of experience in vacuum pump filter. We will continue to share the knowledge of vacuum technology especially about the vacuum pump filters. If you would like to inquire about filters, please feel free to contact us.

Post time: Jan-10-2024